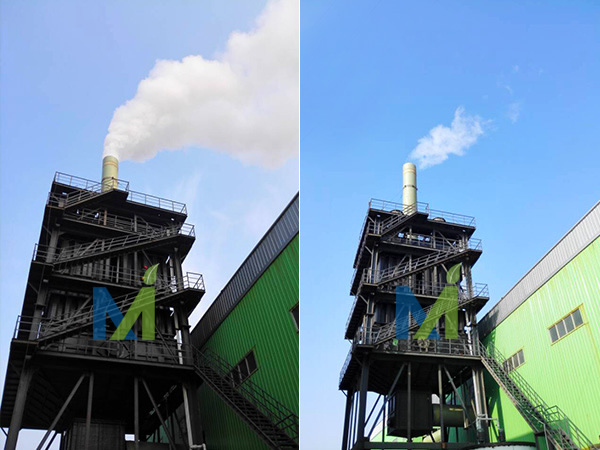

Comparison Diagrams of the Effects of Wet Electrostatic Precipitators for Zinc Smelting in Ningxia before and after

The waste gas from the rotary kiln is treated by a settling chamber for dust removal, multi - stage surface - cooling dust collectors, a desulfurization tower, and a washing tower. The waste gas from the distillation furnace is treated by a waste heat boiler and a bag filter before entering the wet electrostatic demister. After being treated by the wet electrostatic precipitator, it meets the environmental protection emission requirements, and normal production can be carried out. The above figure shows the comparison diagram before and after operation.

Ningxia Ninghua Technology Co., Ltd. is located in the New Material Circular Economy Demonstration Park in Zhongning County. The total investment of the project is 530 million yuan. It can process 50,000 tons of waste slag annually and comprehensively recover 20,000 tons of zinc oxide. The zinc oxide is mainly used to produce 10,000 tons of distilled zinc in the distilled zinc production line.

+86-18633235200

+86-18633235200