Wet electrostatic demisters have been widely promoted and applied in the field of humidity purification of desulfurized wet flue gas. As a new type of high - efficiency purification and dust (mist) removal equipment, the honeycomb - type conductive FRP electrostatic demister offers excellent economic and environmental benefits. It has been popularized and used in the power, chemical, glass, cement, and metal smelting industries, and holds significant market potential in the field of in - depth purification, which is of great value for environmental protection and the long - term development of enterprises.

The anode (precipitating electrode) of the wet electrostatic demister is an electrostatic demister made with synthetic resin as the binder, glass fiber and its products as the reinforcing material, and graphite and carbon fiber products as the conductive material. It features good electrical conductivity, light weight, corrosion resistance, good flame retardancy, stable performance, and high demisting efficiency.

Wet electrostatic demisters in operation across different industries

Electrostatic demister

(1) Wet electrostatic demister body

The body of the WESP adopts a circular structure with specifications of Φ9.2m×10.7m. The upper part is equipped with a flue gas deflector and a gas distribution plate, while the lower part is provided with a liquid collection tank. The total height is approximately 14m (including the top cover and the lower collection tank). The outer shell is made of carbon steel lined with glass flakes. The outlet flue of the WESP is located on the side of the body and is directly connected to the existing vertical clean flue, which reduces the flue gas resistance and prevents the purified flue gas from re - entraining water. The collected liquid flows into the slurry tank by gravity and is pumped back to the absorption tower by a water pump.

(2) Wet electrostatic demister anode device

The anode device includes the precipitating electrode, support beams, flushing water pipes, and support beams. The anode tube (also known as the precipitating electrode) is made of advanced conductive glass - reinforced plastic, which has good electrical conductivity and is easy to flush. The upper and lower ends of the anode membrane are supported and tensioned by support tubes. The upper support tube also serves as a flushing water pipe, through which the six surfaces of the anode membrane can be flushed online to prevent scaling on the anode membrane. The four layers of support tubes above and below the anode membrane are respectively supported by four support beams. The upper support beam of the anode membrane is fixed to the tower wall, and the lower support beam adjusts its height through the adjustment mechanisms at both ends to tension the anode membrane. The precipitating electrode adopts a glass - reinforced plastic honeycomb structure. Compared with the circular tube structure, the honeycomb structure has a higher cross - sectional area utilization rate, and the glass - reinforced plastic material has advantages such as good electrical conductivity and long service life.

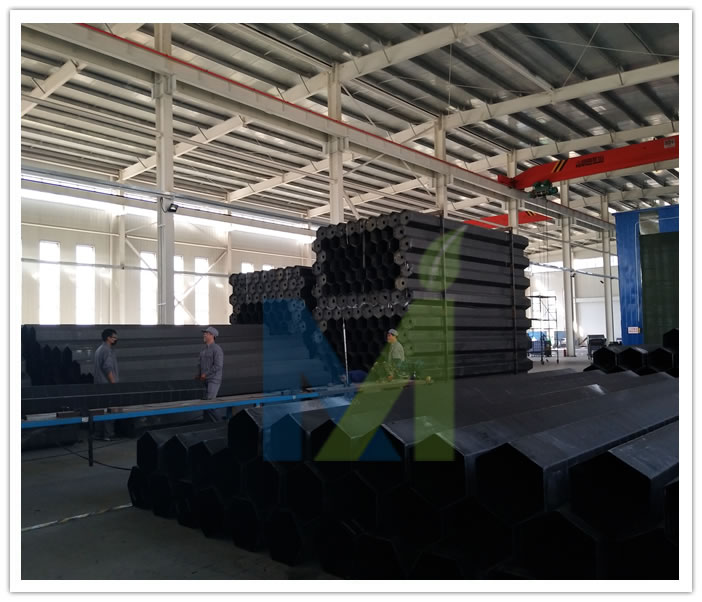

A corner of the production workshop for the conductive glass - reinforced plastic anode tubes of the Weimei wet electrostatic precipitator anode system

(3) Wet electrostatic demister cathode device

The cathode device includes the cathode wire, upper and lower suspension devices, and an insulation box. A cathode wire is arranged at the center of each anode hole. It is of the barbed type and made of lead - antimony alloy. The cathode wire is fixed on the upper and lower frames, and the frames are supported by the insulation box. The suspension rod in the insulation box is supported by a quartz tube. By introducing hot air into the insulation box, the cathode device is always kept in a dry and insulated state from the anode and the tower body. The electrostatic demister is equipped with one electric field, which is powered by a high - frequency, high - voltage DC constant - current power supply through an insulation box. A total of eight insulation boxes are installed above and below the demister. A layer of flushing water device is arranged above the wet electrostatic demister to periodically flush the cathode wire (the flushing cycle of the cathode wire is 15 - 20 days).

The cathode wire of the electrostatic demister

The wet electrostatic demister in the phosphoric chemical industry operates up to the standard.

+86-18633235200

+86-18633235200