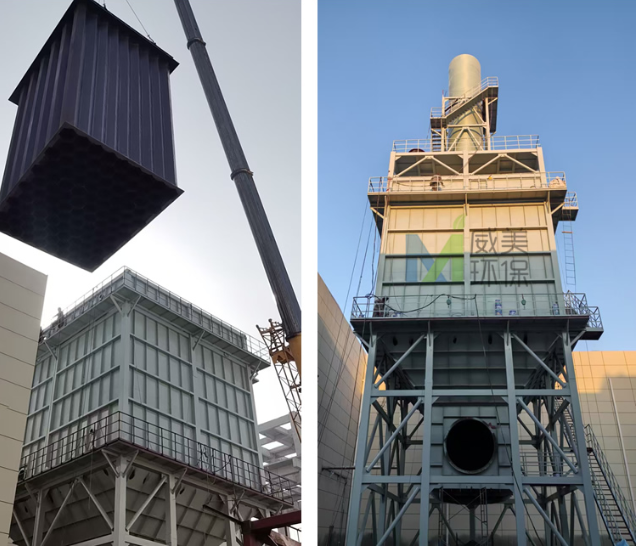

The wet electrostatic precipitator, made of 2205 material and designed for flue gas treatment at the front-end of the yellow phosphorus furnace, has been officially put into operation.

wet electrostatic precipitator, made of 2205 material,has been officially put into operation.

The flue gas handling capacity of this equipment is ≤ 80,000 m³/h, the flue gas temperature is ≤ 90℃, the working pressure is ≤ 7,000 Pa, and the designed flow velocity of the demister is ≤ 1 m/s. Since the flue gas is from the front-end of the yellow phosphorus furnace and contains highly corrosive media such as sulfur, phosphorus, arsenic and fluorine, the anode tubes, upper shell, middle shell and lower shell of the wet electrostatic precipitator are all made of 2205 duplex stainless steel. With its excellent impact toughness and outstanding overall and local corrosion resistance, it ensures the stable operation of the entire equipment system.

The wet electrostatic precipitator has been delivered to the customer and put into use (visually smokeless).

+86-18633235200

+86-18633235200