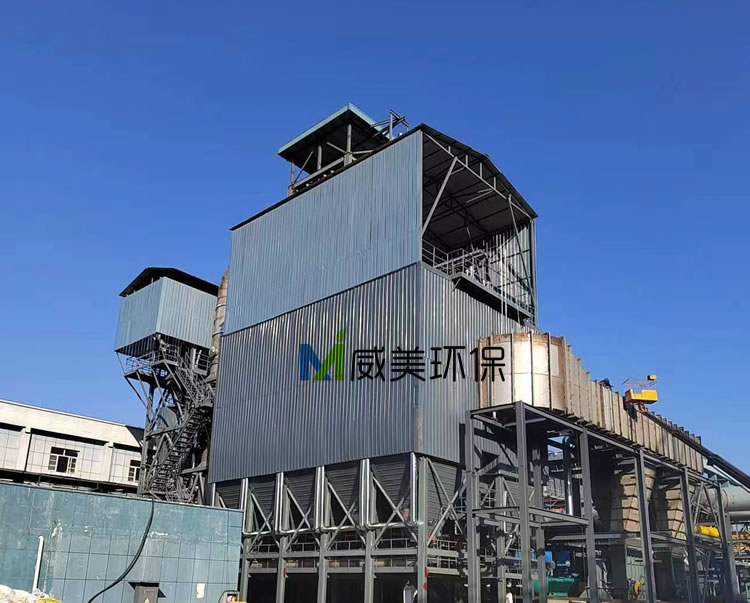

The illustration depicts a 100t/h high-temperature and high-pressure gas boiler (540℃, 9.8MPa) flue gas pretreatment system designed and manufactured by Hebei Weimei Environmental Protection. This system employs sodium carbonate (Na2CO3) as the flue gas treatment agent and utilizes a baghouse dust collector for particulate removal. The flue gas pretreatment system comprises four major components: the raw material silo, feeding system, mixing and drying system, and bag dust collector.

The baghouse dust collector system in Guizhou has been successfully commissioned and is operational.

Given the high concentrations of sulfur, phosphorus, and other acidic substances in the flue gas of this project, the pretreatment system has been meticulously designed to address corrosion concerns. All flue ducts within the system are constructed using materials no less than 2205 or 316L grade stainless steel.

The production site for the bag dust collector in the comprehensive utilization project of yellow phosphorus tail gas is currently active.

The bag dust collector system consists of multiple integrated components: the collector body, hopper system, clean air chamber, filter bag assembly, cleaning system, stair system, compressed air pipeline and connectors, inlet/outlet flue ducts, and ash discharge device.

Stainless steel structural components for the flue gas pretreatment system's baghouse dust collector have been dispatched.

The construction site for the yellow phosphorus tail gas bag dust collector project is progressing as planned.

This project employs pure PTFE filter bags for optimal performance.

PTFE (Polytetrafluoroethylene) fiber, derived from fluorite, exhibits exceptional thermal properties with a melting point of 327℃ and instantaneous temperature resistance up to 300℃. This material demonstrates superior characteristics including low friction coefficient, flame retardancy, excellent insulation, and thermal insulation properties. It is highly resistant to oxidation corrosion from various strong oxidants and is virtually immune to hydrolysis reactions. The PTFE fiber maintains excellent filtration efficiency and cleaning performance, with minimal dust adhesion on its surface even under high-temperature conditions.

+86-18633235200

+86-18633235200