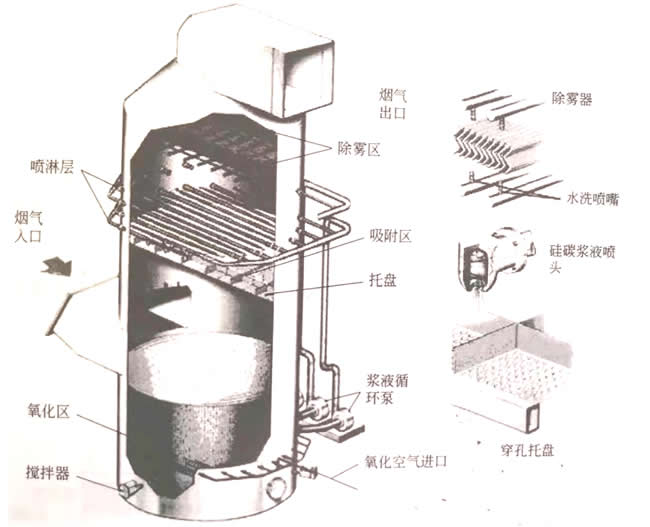

The desulfurization tower body can be circular or rectangular. Flue gas usually enters the tower from the bottom and exits from the top. Deflectors can be used to ensure uniform distribution of the gas flow inside the tower. Limestone slurry is sprayed downward from a relatively high position inside the tower. The absorption surface area for SO2 is provided by the droplets ejected from the nozzles. There are 3 - 6 spray layers in the spray zone, and the nozzles are arranged on the spray layers at different heights inside the tower. At different spray layers, an appropriate number of nozzles are arranged in a cross - pattern to achieve the optimal spray coverage rate on the cross - section inside the tower, generally ranging from 200% to 300%. Although there are other methods, the most common approach is to have one slurry pump corresponding to one spray layer. The number of slurry pumps can be adjusted according to the desulfurization rate corresponding to the load of different boilers and the sulfur content of the coal. Most of the slurry droplets fall into the absorption tower body and are collected by the reaction tank inside the absorption tower. Due to the certain size range of the droplets ejected from the nozzles, some small droplets are carried by the flue gas to the upper part of the absorption tower and removed by the demister. Most demisters are horizontally installed at the top of the absorption tower, but they can also be vertically installed in the outlet flue.

The desulfurization tower manufactured by Hebei Weimei Environmental Protection for a brick factory in Shandong

The main function of the desulfurization tower is to absorb SO2. The factors that mainly affect the SO2 removal rate include the flue gas flow rate, the slurry spray volume, the height of the spray layer, and the SO2 concentration of the inlet flue gas.

Internal structure diagram of the desulfurization tower

In the limestone - gypsum desulfurization device, the desulfurization tower has become a common type of absorption tower and is a typical spray absorption tower. Most desulfurization towers are arranged in a counter - current manner. The flue gas enters the absorption tower from the lower part of the spray zone and comes into counter - current contact with the uniformly sprayed absorption slurry. The flue gas flow rate is usually 3 - 5 m/s. The liquid - gas ratio is closely related to the sulfur content of the coal and the desulfurization rate, generally ranging from 8 to 25 L/m3. The advantage of the spray tower is that it has fewer internal components, a lower possibility of scaling, and a smaller pressure loss. Counter - current operation is beneficial for the full contact between the flue gas and the absorption liquid, which improves the absorption efficiency, but the resistance loss is greater than that of co - current operation.

+86-18633235200

+86-18633235200