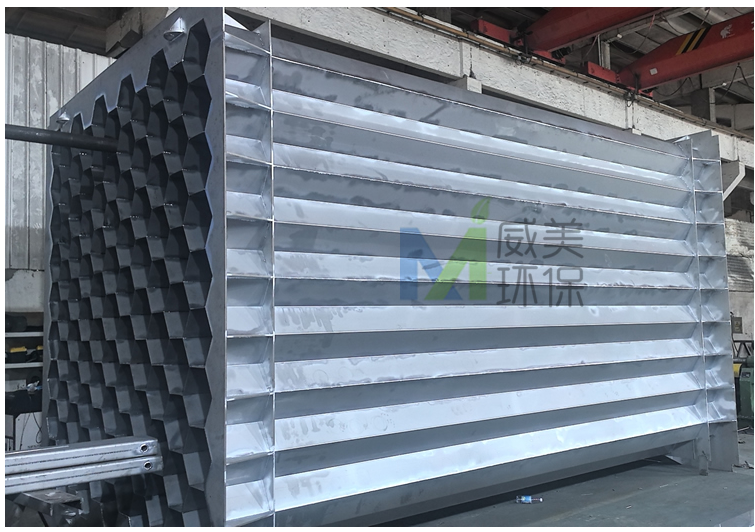

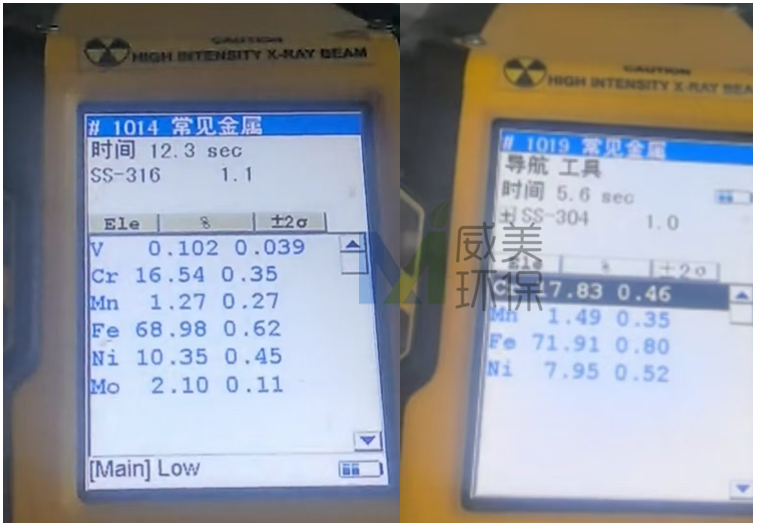

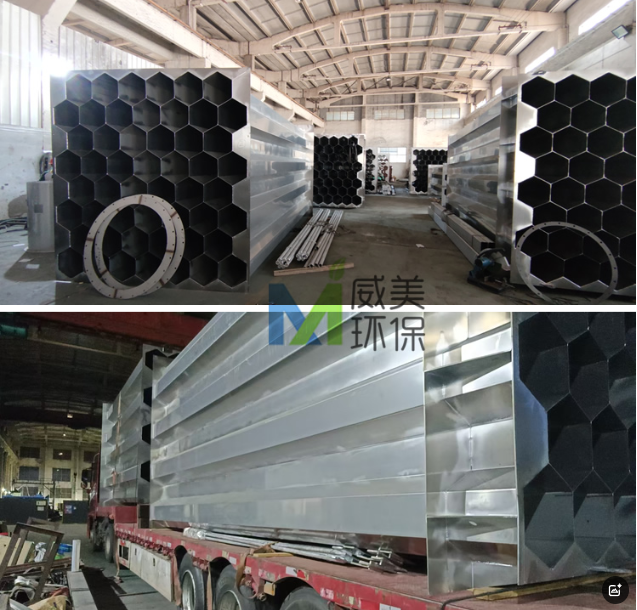

The wet electrostatic precipitator (WESP) made of 2205 material for flue gas collection at the electric furnace front is dispatched by road. The flue gas volume of this WESP is ≤ 80,000 m³/h, the flue gas temperature is ≤ 90℃, the working pressure is ≤ 7,000 Pa, and the designed dust removal flow velocity is ≤ 1 m/s.

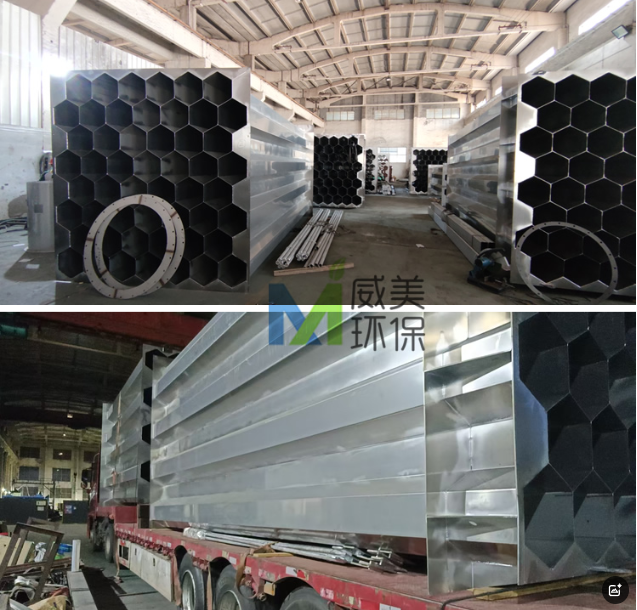

Road Dispatch Site of the 2205 Material Wet Electrostatic Precipitator for Flue Gas Collection at the Electric Furnace Front

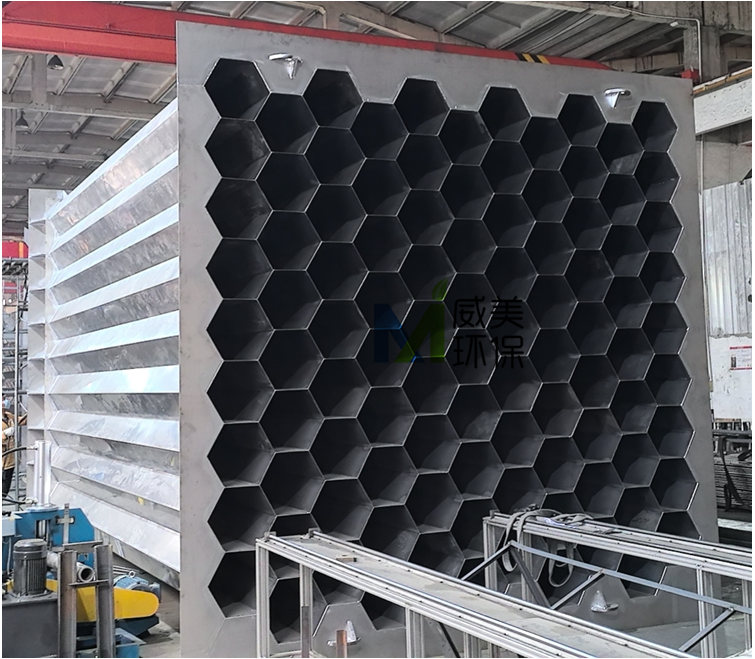

The flue gas treated by this wet electrostatic precipitator is the flue gas at the yellow phosphorus furnace front, which contains highly corrosive media such as sulfur, phosphorus, arsenic, and fluorine. A flow equalization device is equipped at the inlet of the demister to ensure that the flue gas can flow through the electric field better and more evenly. The material of the flow equalization device must meet the operating environment requirements of the wet flue gas after desulfurization. The power supply of the entire system is designed with a PLC automatic control system, which automatically controls spraying and cleaning. Meanwhile, the PLC system reserves a communication interface, and all data can be uploaded to the DCS control room.

Arrival Site of the 2205 Material Anode Tubes for the Wet Electrostatic Precipitator

+86-18633235200

+86-18633235200